Elastin as artificial muscle material

Artificial muscle from proteins for diverse future applications

As far as diversity and complexity are concerned, proteins are nature's smallest marvels. Biotechnologists have already used natural proteins as a basis for the development, bespoke design and production of artificial systems. This is what the livMatS cluster of excellence at the University of Freiburg has been doing. Researchers in the cluster have successfully produced an artificial muscle from elastin that functions autonomously. Potential future applications include soft robotics, nanotechnology, pharmaceutics and biomedicine.

Dr. Stefan Schiller and his research group in the livMatS cluster of excellence have developed an artificial muscle. © private

Dr. Stefan Schiller and his research group in the livMatS cluster of excellence have developed an artificial muscle. © privateA major medical goal of the future is to be able to biotechnologically produce the body's own tissues as needed. We have now actually come a little closer to achieving this: researchers in the University of Freiburg’s 'Living, Adaptive and Energy-autonomous Materials Systems' (livMatS) cluster of excellence have successfully developed an artificial muscle from natural proteins that is capable of contracting autonomously. Contractions can be controlled with the help of pH value fluctuations and temperature changes and fuelled with the help of a chemical energy source.1)

"However, we are still a long way from being able to produce a muscle replacement for seriously ill patients, so we don't want to raise false hopes," says Dr. Stefan Schiller, who is leading the work at livMatS. "Nevertheless, some very practical applications for the artificial muscle are quite conceivable."

Elastin as the protein of choice for artificial muscle

Researchers in the livMatS cluster of excellence in Freiburg specialise in bionic chemistry - the development of life-like material systems inspired by nature. "We are looking for molecular solutions that are an exact fit. We therefore focus mainly on proteins as we can design them according to our needs. They have great potential for all kinds of applications in medicine and technology. For example, we have developed an interesting biological adhesive that is protein-based. Another advantage is that protein-based materials are ecological and regenerative."

In the course of their experiments with the biomolecules, the researchers also came up with the idea of constructing artificial muscle systems from proteins. Natural muscle fibres, which together with the skeleton, enable movement, are made of contractile proteins, actin and myosin filaments. "However, these proteins are not as well suited for artificial muscle that is supposed to respond to different stimuli," Schiller reports. "Instead, we chose elastin-derived proteins because it was known that these elastin-like molecules can respond to different stimuli. And they have other advantages that their natural counterparts don't. For example, the characteristic domains are only five to six amino acids long; so it's easier to rationally design their properties and thus alter the biophysical properties of the muscle." Elastin is a natural fibrous protein that occurs in humans. However, it does not occur in muscles but in skin and blood vessels, giving these structures elasticity.

First fully biobased system

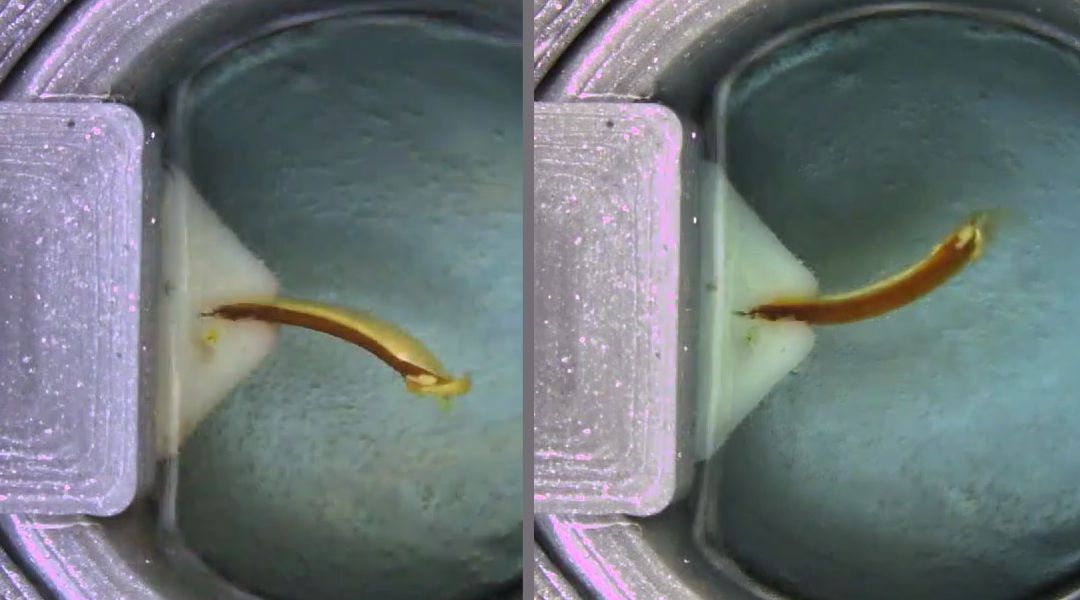

Movements of the artificial muscle can be triggered by changes in environmental conditions, e.g. pH. The basis for this autonomous contractility is the two-layer structure consisting of protein variants with different properties. © Matthias Huber

Movements of the artificial muscle can be triggered by changes in environmental conditions, e.g. pH. The basis for this autonomous contractility is the two-layer structure consisting of protein variants with different properties. © Matthias HuberThe idea of developing artificial muscles is not new: muscle systems based on polymers and tiny molecular machines already exist in different variants. However, up until now it had not been possible to produce muscle materials that are completely biobased in the laboratory. The livMatS research team therefore pursued a completely different approach from the outset: the artificial muscle not only needed to simulate the living system, but also consist entirely of biobased material. The result is a novel tissue consisting solely of proteins that are derived from the body's own protein sequences and contract autonomously.

To construct this muscle, the researchers have developed two elastin-derived proteins and produced them biotechnologically in Escherichia coli bacteria: one of the proteins responds to fluctuations in pH, the other to changes in temperature. The principle of autonomous motility is based on the different properties of the two molecule variants. The scientists combined the two proteins by means of photochemical cross-linking to form a bilayered material. Changing the environmental conditions thus enabled the researchers to induce the material to contract autonomously in a cyclical manner: an oscillating chemical reaction, during which the pH changes in cycles, causes the pH-sensitive variant to expand, prompting flexion, then contraction of the muscle, resulting in opposing movements. "You can think of it as similar to a protein-analogous bimetal," Schiller said.

Simple system for learning and forgetting

The researchers were also able to switch the rhythmic contractions on and off by changing the temperature: the oscillating chemical reaction starts at a temperature of about 20°C; cooling it down stops the reaction. "The material makes rhythmic movements in a kind of semi-flow reaction for several hours," the scientist explains. "In addition, we can programme certain states that the material can adopt and reset them again with another stimulus. We have thus achieved a simple system for implementing learning and forgetting at the material level."

The artificial muscle can be imagined as a small, gelatinous protein gel: "It is itself a kind of hydrogel in a measuring cell in an aqueous medium," Schiller explains. "As proteins need a moist environment, the degree of hydration must be high. When cross-linked, the muscle can be removed from the aqueous medium, but it then dries out quickly, which changes the structure and properties."

Chemical fuel provides energy for contractions

However, the artificial muscle is not a perpetual motion machine. The contractions consume energy, which must be provided in the form of a fuel. For this purpose, the experts used a chemical energy source - sodium sulphite - which was made permanently available as a solution via a tube. "It would also be conceivable to develop the material further to respond to and consume other energy sources, such as malate derived from biomass," says Schiller. "In general, however, the system is flexible enough that it could be developed further to respond to other stimuli, such as salt concentration changes in the environment or an electrical stimulus. That’s what we are looking to do now. It would then be conceivable to use it to establish a new form of energy generation and storage."

Thus, the ability to adjust the composition of the artificial muscle to match particular tissue might pave the way for interesting future applications. The artificial muscle from Freiburg with its high adaptability thus opens up a variety of interesting perspectives: from autonomous, biobased and biocompatible robots that act as quasi-living machines; applications in reconstructive medicine and pharmaceutics as an interesting system for drug formulation and transport and an intelligent material for soft robotics that mimics the movements of living organisms.

The researchers are now looking at further ways to develop the muscle. For example, they would like to try to produce it by 3D printing, thus making it an easily accessible material. "In this way, it could perhaps also be made available for regenerative processes at some point in the future. Our vision would be to be able to use the material for wounds," the researcher said. "You probably won't be able to replace the body's own muscle function, but it would be a nature-based alternative to conventional prostheses, which themselves are no more than machine components in the body."