Pipetting robot for academic research

goodBot GmbH: a third arm for researchers

Repetitive daily tasks that researchers have to conduct in the laboratory tend to be tiring and often lead to errors. Precise pipetting is, however, crucial for achieving reproducible results. Automation is underrepresented in research laboratories and existing pipetting robots are unsuitable for scientists. This is why Dr. Julius Wiener, Tobias Zundel and Oliver Brunner decided to found the company goodBot GmbH and develop a pipetting robot tailored to academic research.

Precision in science labs very much depends on correct experimental procedures being followed, with liquid handling, i.e. pipetting, being the most crucial factor and at the same time the most significant source of errors. Dr. Julius Wiener views manual pipetting as a major hurdle because the human hand is much less accurate than a mechanical one. "When you have to do the same thing 500 times and you get distracted, you quickly lose track," says Wiener. The molecular biologist often felt like a pipetting robot himself during his university career and repeatedly asked himself whether it was really necessary to pipette everything by hand or whether this monotonous task could be better and more reliably performed by a robot. Failed experiments are costly, consume valuable materials and take time that could be put to better use elsewhere.

Liquid handling in most laboratories is manual

Wiener was surprised that even during master's and doctoral research, pipetting was still done manually. Although robots have long been established in diagnostics and industry, this is only the case in four percent of research laboratories. To understand the lack of automation, Wiener examined a pipetting robot he received as a gift, which its previous owner had not taken out of the box. "That's when I understood why research labs don't want these devices; they are super cumbersome to operate and not designed for flexibility," he says. When carried out manually, a typical experiment takes around two hours, while data inputting and handling error messages also takes two hours. Although such devices are well-suited for diagnostics, in any daily research routine that involves constantly changing experiments, the effort required to set up a robot clearly outweighs the benefits.

Unsure whether to pursue an academic career

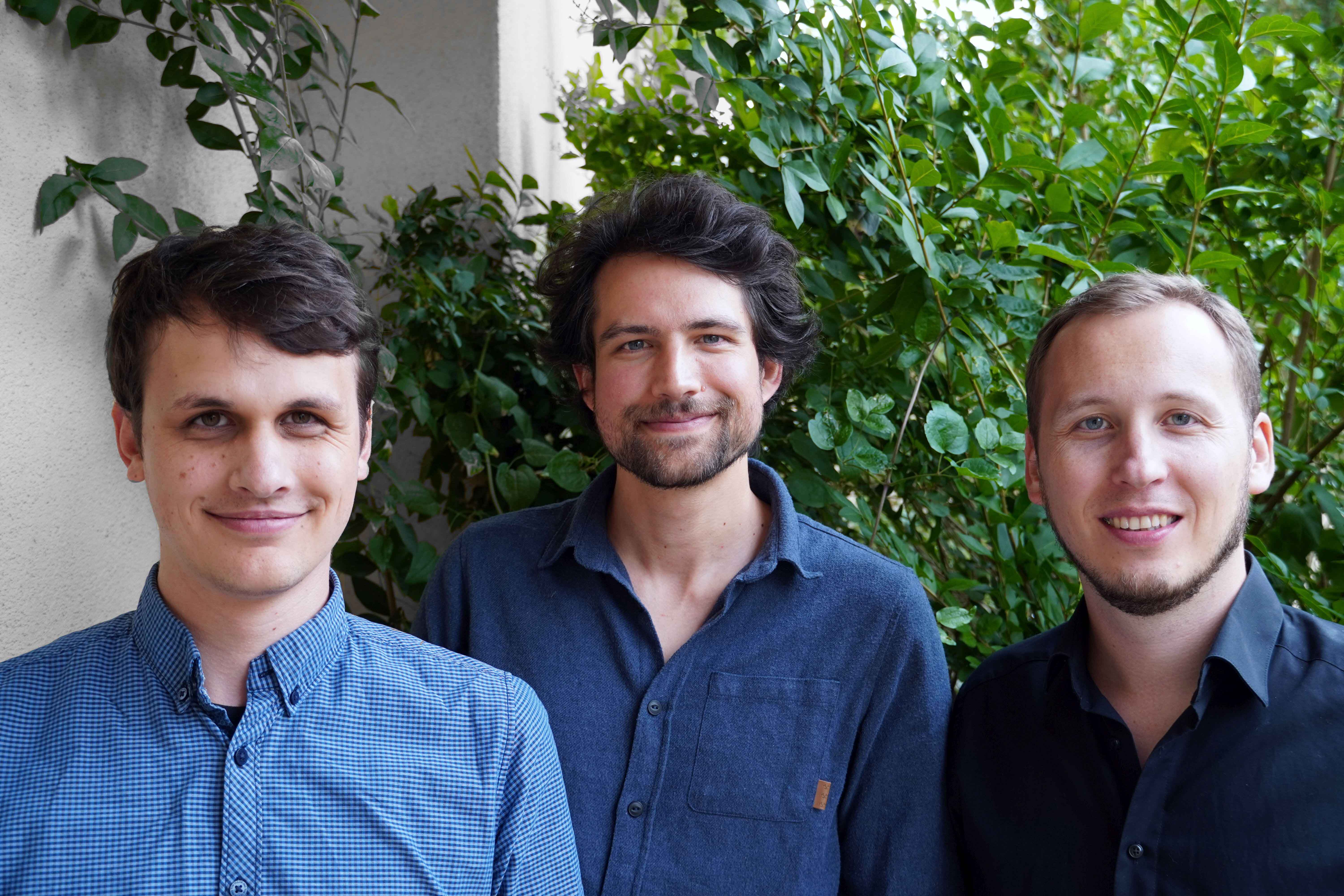

The three goodBot GmbH founders: Oliver Brunner, Dr. Julius Wiener, Tobias Zundel (from left to right) © goodBot GmbH

The three goodBot GmbH founders: Oliver Brunner, Dr. Julius Wiener, Tobias Zundel (from left to right) © goodBot GmbHWiener didn’t initially plan to start a company, but a predetermined path through the university system didn’t seem right for him either. Born in Überlingen on Lake Constance in 1988, Wiener was determined to become a biologist so he could discover plants and study their active ingredients. After studying biology in Tübingen and earning a master’s degree in molecular biology in Darmstadt, he travelled through the Alps, Corsica, South America and Southeast Asia to reconsider his career path. "You get pushed through the system and do a bachelor’s and a master’s just because that is what everyone else is doing. I didn’t really feel comfortable with that," he recalls. He nevertheless earned his PhD at the Department of Microsystems Engineering (IMTEK) at the University of Freiburg in microfluidics, which sits at the intersection between technology and biology. Wiener refers to it as the miniaturisation of experiments. During his doctoral studies, Wiener’s focus increasingly shifted toward method development, and he once again realised that the academic environment didn’t suit him.

The agile pipetting assistant

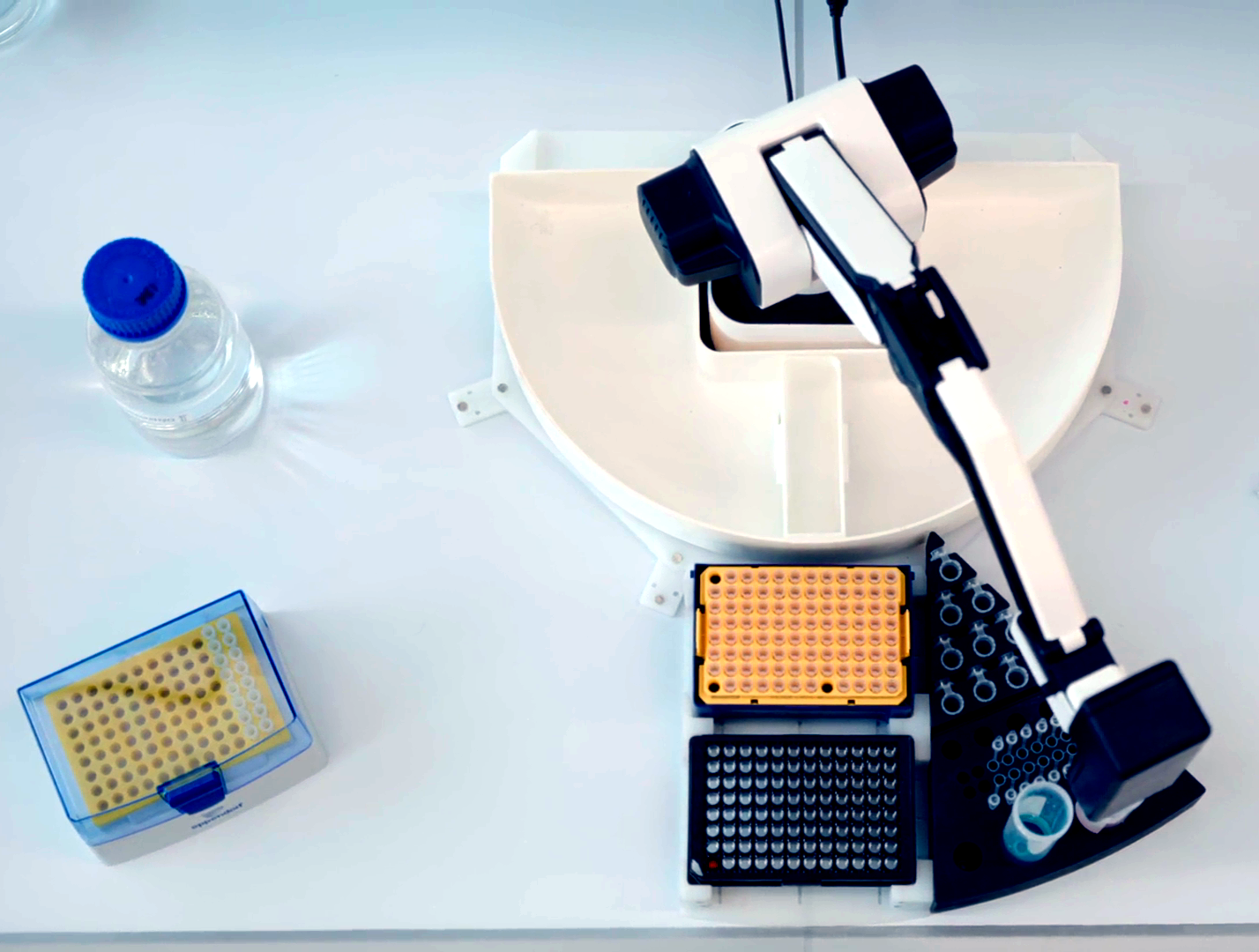

The ‘good robot’ (goodBot) is designed to be a time-saving personal pipetting assistant for researchers in science laboratories. © goodBot GmbH

The ‘good robot’ (goodBot) is designed to be a time-saving personal pipetting assistant for researchers in science laboratories. © goodBot GmbHWiener once again thought about finding solutions using robots to make researchers’ work easier. His interest in robotics, programming and 3D printing helped him in this endeavour. His primary goal was not to start a company; he just enjoyed tinkering and experimenting. His boss at the time told him he couldn’t buy any more lab equipment that would take hours of training to use. So he thought to himself: "How hard can it be to build a robot?"

A common issue with existing systems is their size and cost, coupled with regular ongoing expenses for items such as special pipettes and vessels. Wiener therefore aimed for a flexible, easy-to-use automation solution that works with already available materials. Since research is conducted at various workstations, the goodBot needed to be compact, portable and integrable into any environment. The device developed by Wiener is no bigger than a desk lamp and has a robotic arm that can move freely and perform all tasks that standard pipetting does. In addition to the user-friendly software, a significant advantage is the time saved, which can be put to good use developing ideas or analysing experiments: "If I want to do a PCR, it takes me five minutes as a new user of the goodBot and two minutes as an experienced user," says the founder. Furthermore, goodBot increases repeatability and ultimately the success rate, resulting in reproducible results.

The birth of goodBot GmbH

Vessels can be used in variable sizes from 1 μl to 1 ml. The goodBot software is also extremely user-friendly and requires no additional training. © goodBot GmbH

Vessels can be used in variable sizes from 1 μl to 1 ml. The goodBot software is also extremely user-friendly and requires no additional training. © goodBot GmbHWiener describes himself as adventurous, which led to him deciding to turn his idea into a company. "I quickly realized that it wasn't going to work as a one-man show," he says. "I don't know much about business or software development." During the pandemic, it was hard to find people willing to start a company. However, in late 2020, he met Tobias Zundel, an experienced business engineer, through the Freiburg student platform Foundersclub. Wiener worked with Zundel and the Freiburg Founder's Office to apply for and obtain an EXIST start-up grant. Computer scientist Oliver Brunner subsequently joined the team on the software development side. From there, the start-up took off, although obtaining public funding proved to be challenging. While the EXIST grant and early financing through Start-up BW Pre-Seed before market entry were secured without much bureaucracy, subsequent financing was very hard to come by. "Based on the queues at our booth at trade shows, it was clear that there was huge customer interest in our product, but we didn't have the money to produce on a large scale," says Wiener. The follow-up financing after market entry proved to be so start-up-unfriendly that it was almost impossible to secure other investors. "Start-ups are supported up to market readiness, and when they need to reach a certain production level, they are left on their own," says the entrepreneur. "This gap in funding is very unfortunate!"

Despite these hurdles, goodBot entered the market in early 2024, and the first goodBots have already been sold. Wiener and his team are working on further developing the robot, which will be able to heat, shake, stir and adjust vessels in the future. Additionally, the team is developing an online portal as part of the product, where researchers can share their experiences and experiments with each other, thus expanding their network.

Initial reports indicate that the goodBot pipetting robot makes daily life significantly easier in research laboratories by taking over monotonous tasks and delivering reproducible results. This allows researchers to focus on their core competencies in research. The flexible, easy-to-use automation solution from Freiburg demonstrates how innovations from science can improve everyday lab work.