Expert interview

Learning from Nature for Innovation

Natural phenomena are used to find technological solutions in a number of fields. In an interview with BIOPRO, Prof. Dr. Peter M. Kunz discusses groundbreaking innovations emerging from Baden-Württemberg and shares insights on how the principles of bionics can inspire the next generation of innovators.

Prof. Dr. Peter M. Kunz organises the Bionik-Kongress every two years. © Prof. Dr. Peter M. Kunz

Prof. Dr. Peter M. Kunz organises the Bionik-Kongress every two years. © Prof. Dr. Peter M. KunzProfessor Kunz, how do you define the term bionics?

The term bioinics is a compound word formed from the words biology and technics. VDI (Association for German Engineers) Guideline 6220 Sheet I provides a comprehensive definition of bionics, but I would say that my self-explanatory definition - 'learning from nature for innovation' - implies much more than what is stipulated in the VDI guideline, to which I have contributed. I believe it’s crucial to inspire young people to engage in 'learning from nature for innovation' and to encourage them to contribute their own ideas. The only thing you need is a straightforward set of methodological tools. You’ll then be able to use the tools to systematically deconstruct a complex problem into its core components to identify the crucial bottleneck. By articulating this 'crux of the matter' concisely, you can often find a corresponding analogy in nature.

Can you give some examples of bionic developments and innovations?

A prime example of this innovative approach is the low-noise fan developed by Ziehl-Abegg, a fan manufacturer based in Künzelsau. The company’s management challenged its development engineers to create a noiseless fan for cooling spotlights in concert halls to eliminate the distracting humming sound they often make. To tackle this challenge, the Ziehl-Abegg engineers worked together to visualise the fan down into its individual constituent parts. They sat together and managed to pinpoint that the noise was primarily generated by the air vortices that collapse noisily behind the fan blades. Taking their inspiration from nature, the engineers explored the concept of bird wings and sought examples of noiseless flight in nature.

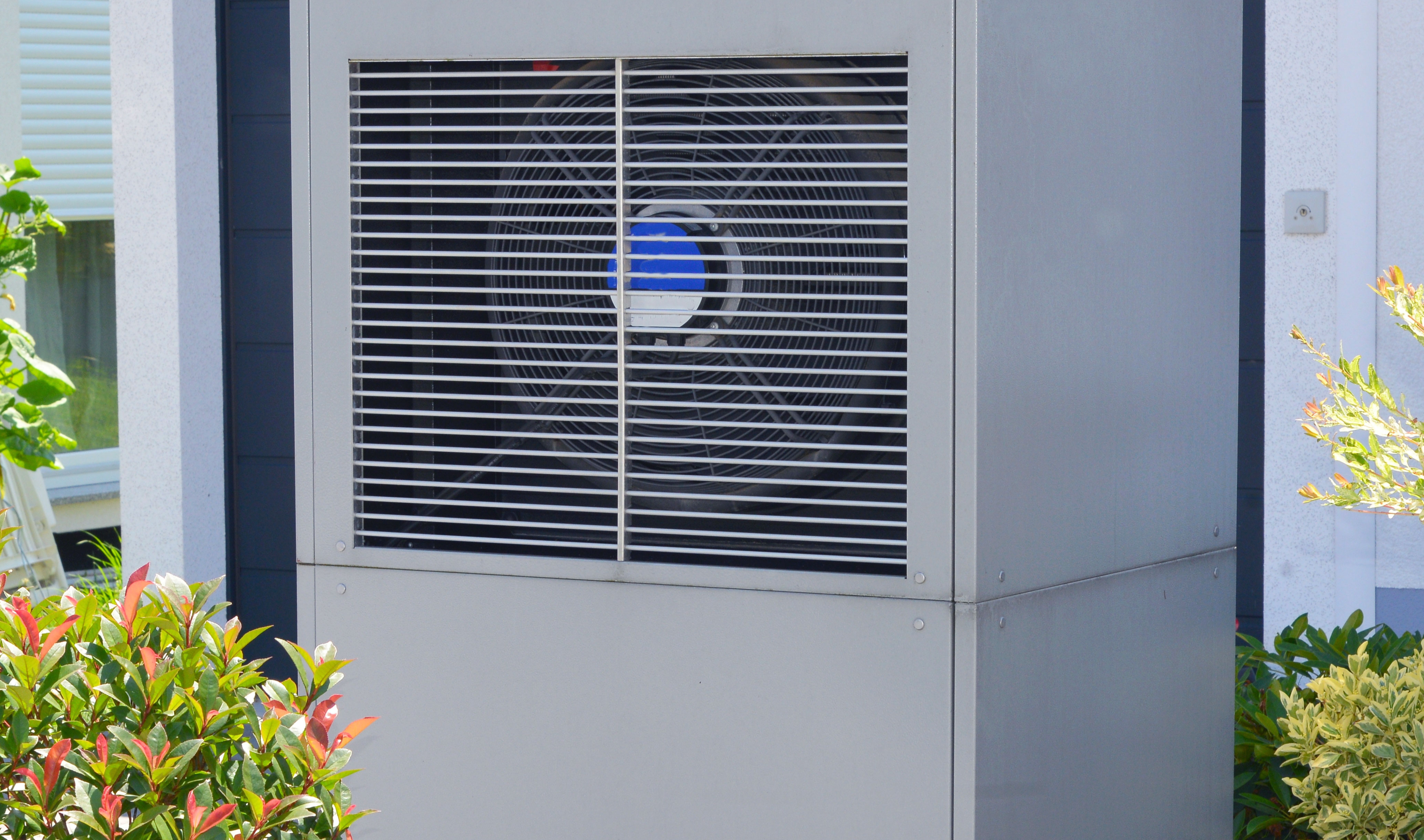

They soon alighted on the example of the owl, a skilled nocturnal predator that flies silently to avoid alerting and scaring off its prey. They used infrared cameras to study the owl's flight dynamics, capturing aerial footage of the birds in forests at night, which enabled them to analyse how air vortices formed in nature and use this for their simulations. By investigating the principles that nature uses to minimise vortex formation, the team was following in the footsteps of Otto Lilienthal, who studied lift in birds to develop machines that could glide through the air. Instead of merely imitating the owl's wing tips, the engineers focused on understanding the underlying aerodynamic effects. This insight led to the creation of their innovative technical product, which was installed in concert halls worldwide until advancements in lighting technology meant it was no longer required. Today, Ziehl-Abegg's low-noise fans are successfully utilised in heat pump systems.

The FE2owlet axial fan was modelled on the owl wing, transferring its contour and structure to the fan blade. © Ziehl-Abegg

The FE2owlet axial fan was modelled on the owl wing, transferring its contour and structure to the fan blade. © Ziehl-AbeggI was approached by the safety engineers of a prominent printing press manufacturer inquiring about a safer, nature-inspired harmless alternative to burnishing bare metal surfaces. The conventional burnishing process involves immersing components in nitric acid at 80°C, a hazardous procedure. To explore alternatives, we visualised the chemical processes involved in theoretical models to understand the reactions occurring on the metal surface due to the highly reactive acid, which create the characteristic black colour. The key reaction is the oxidation of iron hydroxide to black magnetite on the metal surface. To find a safer option, we examined the oxidation potential of hot nitric acid and sought a natural substance with similar oxidation potential. Our research led us to neurotransmitters such as dopamine and serotonin. In laboratory tests, we demonstrated that dopamine can effectively burnish metal surfaces at ambient temperature without posing any risk to operators. However, despite this promising discovery, the surface technology industry has yet to embrace this solution, largely due to the significant cost difference. I cite this example to show that even in highly specialised fields, nature offers viable solutions for technical applications.

Are there applications in the health sector?

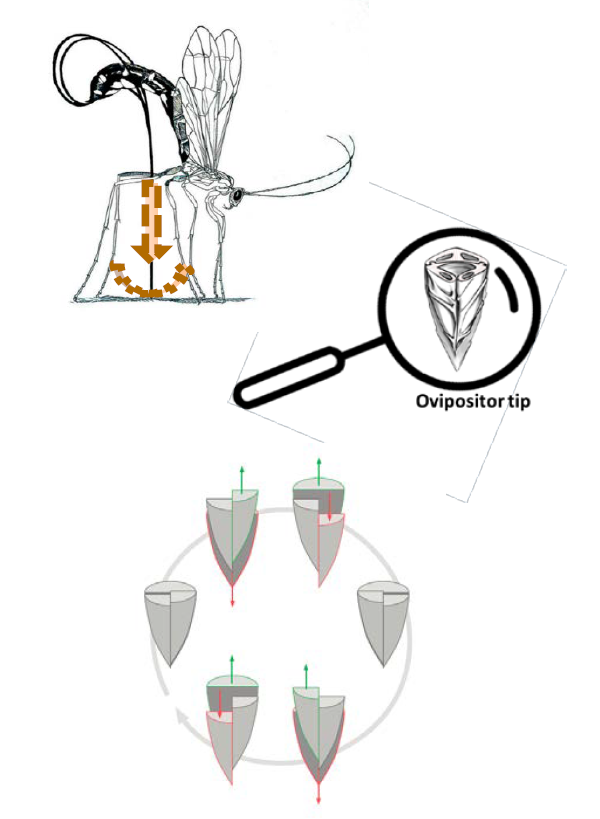

Schematic overview of the pendulum stroke principle. Top: Hymenoptera, including wood wasps, employ a unique non-rotating drilling technique. Centre: Using the ovipositor tip, they drill deep into wood (or other substrates) to insert their eggs into the tree. Bottom: This process requires minimal axial force and no torque. The wasp's ovipositor comprises three components that move in a cyclic pendulum motion, effectively scraping the wood. © Fraunhofer IPA/K. Nakajima

Schematic overview of the pendulum stroke principle. Top: Hymenoptera, including wood wasps, employ a unique non-rotating drilling technique. Centre: Using the ovipositor tip, they drill deep into wood (or other substrates) to insert their eggs into the tree. Bottom: This process requires minimal axial force and no torque. The wasp's ovipositor comprises three components that move in a cyclic pendulum motion, effectively scraping the wood. © Fraunhofer IPA/K. NakajimaOne notable example is the Gecko® tape developed by a company called Gottlieb Binder GmbH in Holzgerlingen. The aim was to create an adhesive, removable connection that would last almost indefinitely. The resulting Gecko® tape adheres exceptionally well to smooth surfaces and can be reused any number of times. Inspired by the gecko, which can effortlessly cling to glass and even walk on ceilings thanks to the adhesive hairs on its feet, this innovative tape stands out from traditional Velcro fasteners, whose development was also inspired by nature, but require a specific counterpart for adhesion. Gecko® tape is widely used in the medical and orthopaedic fields as a residue-free, reusable solution for securing tubes, cannulas, instruments, sensors and more. Additionally, it can effectively attach WLAN routers and displays to glass surfaces or similar materials.

Further nature-inspired products have been developed by Prof. Dr. Oliver Schwarz at the Fraunhofer IPA in Stuttgart. Inspired by the wood wasp, Schwarz’s team has developed a pendulum stroke drill that can create 'rectangular holes', the so-called Sirex drill. Due to such accurate bore geometries, implants can be inserted into the bone with perfect fit, thus preventing them from twisting. The team has come up with a broad range of biomimetic developments that are close to market launch.

You have just founded the 'Netzwerk für Bionische Entwicklungen Baden-Württemberg e.V.'. What is its purpose?

PD Dr. Thomas Stegmaier from the German Institutes of Textile and Fibre Research Denkendorf (DITF) and I have met several times at 'Bio'-centred events to discuss better ways of introducing the concept of bioinics in a broader sense, especially to young people. Along with many others who are passionate about 'learning from nature for innovation', we recognise that there is still a vast untapped field of innovation inspired by natural phenomena.

With this goal in mind, we have been talking to other people and organisations to share our experiences and find ways to equip curious individuals, particularly young people, with the methodological tools for 'bionic development'. Just under six months ago, we came up with the idea of compiling a comprehensive list of bionic competencies in Baden-Württemberg. I reached out to colleagues from various companies, institutes and universities to gauge their interest in working with us on the idea of learning from nature for innovation, and share their knowledge and methods of bionic development with our next generation of talent. In Germany, you need at least seven founding members to establish a registered association. At our founding meeting on October 15, 2024, we were pleased to have 23 participants join us in this endeavor.

We aim to use our network to engage employees in various companies who are interested in incorporating the 'learning from nature for innovation' mindset into their work processes. We will facilitate the sharing of our experiences in independent bionic development and organise collaborative projects designed to disseminate and promote this innovative way of thinking.

Our goal is to empower individuals and organisations to become self-sufficient in their bionic development efforts. We aim to assist companies in gaining hands-on experience, enabling them to independently tackle future projects with confidence. We will provide customised training and educational materials to support this initiative. Additionally, we seek to connect bionics enthusiasts and foster the exchange of experiences through specialised working groups. Ultimately, we aspire to showcase bionic innovations originating from Baden-Württemberg and boost their visibility.

Will the 6th Bionik-Kongress Baden-Württemberg, held at the John Deere Forum Mannheim on 6 May 2025, help you achieve your goals?

The noiseless fans are integrated into heat pumps. © Ziehl-Abegg

The noiseless fans are integrated into heat pumps. © Ziehl-AbeggThe Bionik-Kongress Baden-Württemberg, which I organise every two years, is designed for young people who have recently completed their training or studies. Participants under 30 years old only pay a participation fee of 30 euros.

At the latest congress, we welcomed 70 attendees in this age group, eight of whom have since secured positions as engineers with companies that were present at the Bionik-Kongress Baden-Württemberg in 2023. What sets this congress apart is its unique format, which is not based on traditional PowerPoint presentations. Instead, in the morning sessions, I interview speakers and we discuss six thematic blocks with the audience. We also take a break, during which participants can enjoy a tour of the John Deere tractor manufacturing facility, our primary sponsor. In the afternoon, we offer three-hour forums limited to 25 participants each. These interactive sessions allow attendees to explore competitive project tasks and gain insights into how the companies that sponsor the congress have successfully developed and marketed their bionic innovations. The Netzwerk for Bionische Entwicklungen Baden-Württemberg e.V. organises the congress, with Bionik Mannheim at Hochschule Mannheim Transfer Gesellschaft mbH overseeing event logistics.

I am particularly thrilled that our Minister of Economic Affairs, Dr. Nicole Hofmeister-Kraut, has agreed to be the patron of next year’s Bionik-Kongress and will present the inaugural 'Bio-Award Baden-Württtemberg: Learning from Nature for Innovation'. This award, details of which will be announced by a dedicated working group within our network later in 2024, invites applications from individuals, companies and research institutions across various disciplines, including medical technology and phytopharmaceuticals. If we receive more than eight submissions, the working group will carefully evaluate and select the finalists. Why eight, you may ask? On May 5, 2025, at the gala evening prior to the Bionik-Kongress Baden-Württemberg, these eight finalists will have the opportunity to present their innovations live to the audience, who will be able to both see and touch them. Unlike other awards, the audience at the gala will vote for the innovation that most resonates with them, making this an engaging and interactive experience.

We plan to promote all submissions through our network to reach both the professional community and any interested parties among the public at large. This will involve online visibility and features in various general publications. Our goal is to significantly raise awareness of 'bionic development' in Baden-Württemberg through this comprehensive campaign.