New polymer for wound care

Thermoresponsive adhesive for pain-free removal of wound dressings

Plasters or wound dressings can only perform their intended function if they adhere securely to the skin. However, they are often painful to remove, and in some cases, damage delicate newly formed tissue. Researchers at the University of Freiburg have developed an innovative polymer that adheres reliably at body temperature but can be easily and painlessly removed, leaving no residue, after being cooled.

Self-adhesive plasters protect open wounds from dirt and germs and also absorb secretions. As the plasters need to adhere securely to prevent slippage during movement, they can be challenging to remove. Ideally, it should only take a quick tug. However, for sensitive skin or more extensive injuries, such as those caused by burns, the removal process can be extremely painful and may even cause further tissue damage. "Conventional wound dressings can cause significant harm, particularly to newly formed tissue," says Prof. Dr. Thorsten Steinberg from the Freiburg University Medical Centre. At the Division of Oral Biotechnology at the Dental Clinic, which focuses exclusively on research, he develops regenerative biomaterials for clinical applications as part of interdisciplinary projects.

Thermoresponsive polymer as a new type of adhesive for wound dressings

Prof. Dr. Thorsten Steinberg and other researchers at the University of Freiburg have developed an innovative adhesive for wound care. © T. Steinberg

Prof. Dr. Thorsten Steinberg and other researchers at the University of Freiburg have developed an innovative adhesive for wound care. © T. SteinbergFor over a century, commercially available plasters have been coated with a zinc oxide rubber adhesive, which provides strong adhesion but is difficult to remove, often leaving residue on the skin. It can also trigger allergies and cause further damage to the injured area. Acrylic resins are now used as an alternative and offer better skin compatibility. However, while they are gentler on the skin, they do not adhere as effectively as the traditional zinc oxide-based adhesives.

As part of a project funded by the Baden-Württemberg Stiftung, researchers from the Institute of Macromolecular Chemistry at the University of Freiburg, led by Prof. Dr. Rolf Mülhaupt, have developed material systems that respond to external stimuli. Several years ago, they discovered a groundbreaking thermoresponsive polymer with exceptional adhesive properties. "The polymer undergoes a phase transition and melts at body temperature, adhering firmly to the skin within 30 seconds. However, when cooled to 0 - 2°C using a cold pack, the material solidifies, loses its adhesive strength and can be removed easily without leaving any residue," explains Steinberg, a biologist who was also involved in the project. Under his leadership, and with the continued guidance of Mülhaupt, who has since retired, a prototype was developed from this promising substance during a subsequent funding phase. This new material has attracted interest from commercial manufacturers of wound dressings.

The synthetic polymer is based on polyvinyl acetate (PVA), a thermoplastic commonly used in medical technology, with side chains esterified with fatty acids. By varying the length and combination of the fatty acids used, the temperature range for the phase transition can be precisely controlled. Steinberg explains, "Determining the correct degree of esterification with myristic acid esters was a complex process, as small changes can significantly impact the temperature range where the phase transition occurs." At body temperature, the side chains fuse, making the material adhesive. Under cooler conditions, a configuration change occurs - the side chains crystallise, causing the polymer to contract and lose its adhesive strength. This bonding and debonding process is reversible, meaning the adhesive can be re-applied or adjusted, e.g., in order to reposition the plaster, without leaving any residue.

Industry is very interested

The development of the polymer was primarily led by Benjamin Stolz, then a doctoral student at the Institute of Macromolecular Chemistry, while Steinberg was responsible for biological and medical evaluation of the material. Steinberg has already demonstrated the safety of the novel material in human cell systems. He has also conducted a small pilot study with a clinical functional prototype, involving ten participants who assessed the product’s properties on healthy skin. "Everyone was very satisfied with the application, and it was shown that the polymer adheres well even to moist skin," says Professor Steinberg

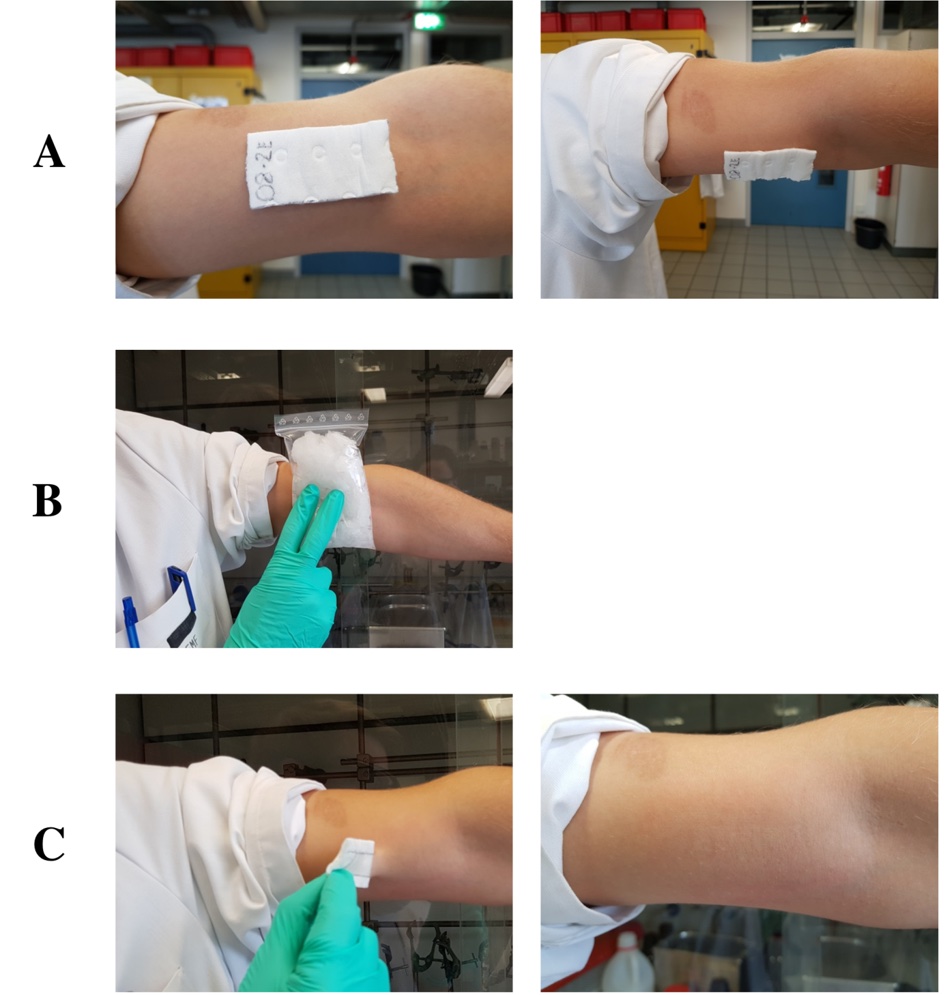

The innovative polymer ensures the dressing adheres securely to the skin at body temperature. It can then be removed painlessly without leaving any residue after being cooled. © B. Stolz, Institute of Macromolecular Chemistry at the University of Freiburg

The innovative polymer ensures the dressing adheres securely to the skin at body temperature. It can then be removed painlessly without leaving any residue after being cooled. © B. Stolz, Institute of Macromolecular Chemistry at the University of FreiburgA patent application has been submitted for the innovative adhesive, and leading manufacturers in the wound care industry have already shown significant interest. Synthesis of the polymer is easily scalable for industrial production, and it can be applied onto standard wound dressing materials using existing manufacturing processes. "We are hopeful that we’ll find a company to take our material, integrate it into their existing products, and bring them to market readiness," explains Steinberg. "Unfortunately, as a university, we are not equipped to do this ourselves." Steinberg and his team are highly committed to translating innovative research into practical applications and keen to bring promising projects to the market to ensure they reach patients.

The researchers receive patent and commercialisation support from Technologie-Lizenz-Büro (TLB) GmbH. TLB has been offering expert advice and tailored service packages for over 25 years designed to maximise the potential of university innovations by taking on the associated risks themselves. TLB operates on a success-based model, earning a 30% commission only if the project proves commercially successful.

The innovative compound doesn’t just work with commercially available wound dressings; it could conceivably be integrated directly into the dressing material itself. This approach would greatly minimise adhesion to newly formed tissue, a frequent issue in cases of wounds that take longer to heal, or burned skin.